Cost remains top challenge for manufacturers

90% say that tariffs above 25% would make exports uneconomical.

Manufacturing leaders continue to prioritise cost optimisation as geopolitical risks necessitate adjustments to offset tariffs, according to a BCG survey.

Amongst respondents, 90% say that tariffs above 25% would make exports uneconomical.

“The cost calculus becomes tougher given that various tariffs can wipe out the advantage that low-cost countries previously offered, particularly in labour-intensive industries,” BCG said.

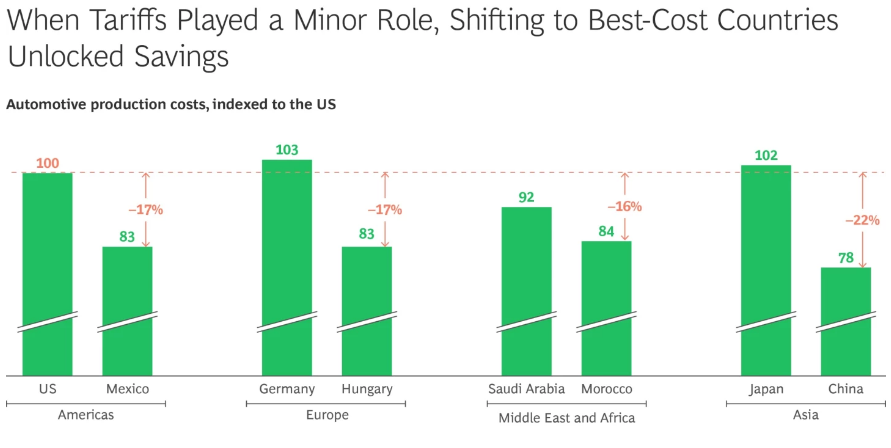

For instance, car manufacturing, where production in countries like China, Mexico, or Hungary, can reduce landed costs to serve higher-cost markets like Germany or the US by 15% to 20% compared with domestic production.

However, BCG said that even when tariffs exceed the threshold where exporting becomes uneconomical, they do not trigger localisation.

“Production typically shifts first to other low-cost countries with more favourable trade terms that can still offer cost advantages over local manufacturing,” BCG noted.

For example, if apparel exports from China to the US become unviable due to tariffs, production is more likely to move to Vietnam, Bangladesh, or India, where labour costs would still be too high for a company to be competitive.

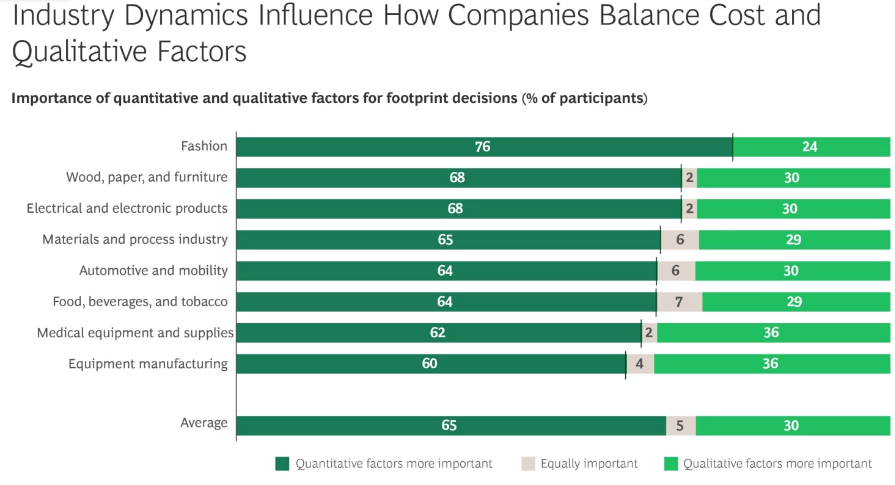

Further, 30% of respondents report that qualitative factors—such as labour quality and political stability—are more important than cost for footprint decisions.

Amongst executives in fashion, 76% of manufacturing executives still prioritise low costs over other considerations. Meanwhile, equipment manufacturing is more likely to cite qualitative factors as more important (36%).

“Companies must weigh cost advantages against qualitative gaps, aligning choices with their risk appetite and business model, as there is no universal ‘best' location for production,” BCG said.

BCG added that manufacturers must build stronger scenario-planning capabilities that allow them to weigh quantitative and qualitative criteria across a range of potential future conditions.

At the factory level, manufacturers must be relentless about controlling what they can control, including increasing productivity through the use of AI and other technologies.