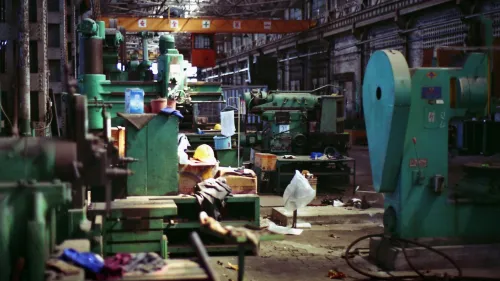

South Korean manufacturing sector battles rising costs and weak demand

Output and orders declined for the second consecutive month.

South Korea's manufacturing sector continued to struggle in November as both production and new orders fell for the second month running, according to the latest industry survey.

The S&P Global South Korea Manufacturing PMI remained unchanged at 49.4 in November, indicating a marginal deterioration in the sector's health. Any reading below 50 signals contraction, whilst figures above 50 indicate expansion.

The data revealed a challenging environment for South Korean manufacturers, with weakness in the domestic economy, particularly in the construction sector, weighing heavily on business conditions.

Production Volumes Decline

Production volumes decreased at a stronger rate than in October, though the overall decline remained modest. Manufacturers cited falling new order intakes and challenging domestic economic conditions as key factors behind the output reduction.

Total new orders fell at the midpoint of the final quarter, marking the second consecutive monthly decline. Firms frequently cited domestic economic weakness whilst also noting the impact of tariffs on sales. Foreign demand also remained subdued, though the rate of decrease was only fractional and had eased from October's level.

Input costs rose markedly during November, with inflation accelerating to reach its strongest level since February. Survey respondents attributed the increase to higher raw material prices and unfavourable exchange rate movements.

Despite mounting cost pressures, manufacturers opted to lower output charges for the first time in a year in an effort to drive sales and remain price competitive. The reduction was the strongest since August 2023, suggesting firms are prioritising market share over profit margins in the current challenging climate.

Jobs and Confidence

Employment levels fell for the second consecutive month amidst lower production requirements. Whilst the decline remained marginal, the rate of job shedding was the most pronounced since July.

Backlogs of work also continued to fall, marking the seventh decline in the past eight months, in line with the trend for new orders.

Looking ahead, the 12-month outlook for output remained positive for the fourth consecutive month. However, the degree of optimism eased compared to the previous month and remained well below the historical average. Confidence centred on hopes for a stronger domestic economy and new product launches to drive demand, though concerns persisted regarding the timing of any recovery, further price fluctuations and increased competition.

Supply Chain Disruptions

Buying activity amongst South Korean goods producers was unchanged in November, following a slight fall in October. Firms reported purchasing inputs in preparation for work on new products, but this was offset by weaker current production requirements.

There were also reports of delivery delays amongst suppliers. Average lead times for input deliveries lengthened to the greatest extent in four months. Holdings of both pre- and post-production inventories were reduced as manufacturers sought to streamline stockpiles whilst demand conditions remained muted.

Expert Analysis

Usamah Bhatti, economist at S&P Global Market Intelligence, commented: "November PMI data signalled that the South Korean manufacturing sector experienced a sustained deterioration in operating conditions. Both production volumes and new orders fell for the second consecutive month, with anecdotal evidence indicating that weakness in the domestic economy was compounded by the impact of tariffs and price fluctuations.

"In fact, input prices rose to the greatest extent in nine months during November, often attributed to higher raw material costs and exchange rate fluctuations. Nevertheless, muted conditions discouraged firms from passing higher costs on to clients, leading them to absorb these costs instead."

"Looking ahead, business confidence remained historically subdued. Concerns were raised regarding the timing of any domestic economic recovery, although firms remained hopeful that new product launches would help drive sales and output over the coming year," he added.

The data suggests South Korean manufacturers face a difficult balancing act between maintaining competitiveness through price cuts whilst managing rising input costs, against a backdrop of weak domestic demand and uncertain global trade conditions.