Digital twin emerging as a must-have tool for manufacturers: McKinsey

A 2022 survey revealed nearly half of industry leaders are using the technology.

Digital twin is proving to be the leading technology for factories globally as it helps manufacturers drive efficiency and rapidly respond to the fast-changing environment, according to McKinsey & Company.

As manufacturers face a slew of challenges from talent gaps to supply chain shortages, factories are now under immense pressure to keep operations resilient to disruptions and ensure operations are future-proofed, the consulting firm said in a January note.

It said more companies are integrating digital twin into their operations to help them make smarter decisions fast and cost-effectively.

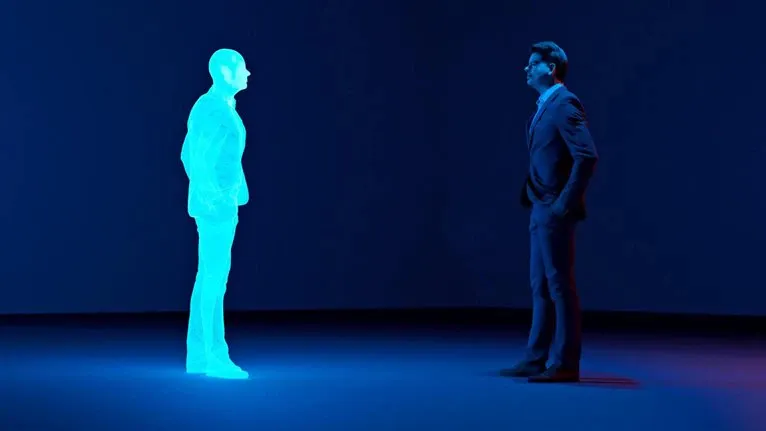

A factory digital twin is a virtual replica of an existing or future factory floor that can simulate outcomes from real-time factory conditions, allowing companies to analyse, interact and test processes and layout changes in a virtual space.

From evaluating spatial parameters for assets such as clearances and employee movement within a cell to predicting production bottlenecks, uses of a digital twin vary depending on the requirements and goals of each facility.

In a June 2022 survey, McKinsey found a whopping 86 percent of senior executives in the sector globally said digital twin is applicable in their production operations while nearly half, or 44% have already rolled out their own systems.

15% of the respondents were planning to implement and the rest still need to get started on that new tech.

Over the next few years, McKinsey sees factory digital twins evolving further with the advent of generative AI. It said high-functioning AI models can make recommendations in real-time and even offer operators solutions to address supply chain disruptions.

“As these models and AI agents become more sophisticated and integrated, they will likely start to interact upstream to understand potential disruptions from the supply chain as well as downstream on changes in demand patterns or shifting customer behaviors,” McKinsey said.

“Digital twins are set to evolve from a nice-to-have technology into a must-have tool for manufacturers of all kinds—and may eventually be required to interact in a fully virtualized supply chain,” it added.

READ MORE: Manufacturing is at a turning point as AI shapes Industrial 4.0