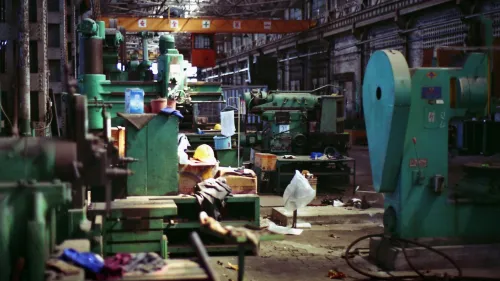

ESG challenges for the manufacturing sector

By Suraj KamathA greener world by empowering data in ESG management and compliance.

The worsening climate crisis marks the need for the world to come together and urgently strive towards a cleaner, greener and more environmentally-conscious direction. While Asia has achieved rapid development and growth in recent decades, today, the continent holds the key to leading the world towards a more sustainable future. For this to happen, Environmental, Social and Governance (ESG) policies need to take precedence for various industries across multiple jurisdictions.

There is an increase in the number of ESG data disclosures in Asia Pacific countries – including several in Southeast Asia where there is mandatory reporting. However, due diligence in the supply chain and regulatory transparency and clarity has been profoundly lacking. With climate change impacting business in more ways than one, from disrupting supply chains and causing fulfilment delays, to the destruction of raw materials and the triggering of natural disasters, more has to be done to steer the world in the right direction. As it is, Southeast Asia suffers the consequences of climate impact, as its coastal regions and archipelago countries make it the most vulnerable region in the world to climate instability.

ASEAN is already on board with ESG compliance with a target to reduce greenhouse gas by 38% by 2030 and a green and low-carbon economy projected to be valued at USD 1 trillion in the same period. The potential of this is big, and according to Mckinsey, CEOs who are already aware of this opportunity have put sustainability and ESG as a top 5 priority in the new normal, and manufacturing firms need to begin investing in technologies and solutions to meet new ESG KPI measurements.

Misconceptions and challenges in ESG adoption

Firstly, many industries closely hold on to the idea that ESG results in poorer financial performance. Unknown to many, ESG and business goals are aligned in many ways. Businesses are always looking to optimise operations to reduce operational costs in terms of energy consumption or manufacturing material. The good news is research has shown a strong correlation between improved financial performance with higher ESG ratings - a pleasant discovery for early adopters in the manufacturing industry.

Secondly, many believe that ESG efforts are a 'prospective cost fallacy' - and expect investments in technology and effort to be unrecoverable. Unfortunately, this perspective is common, as businesses frequently miss the point of ESG, even when ESG and business goals can be synchronised to run in parallel towards greater productivity. There are many facets of sustainability – from energy management to inventory optimisation, and emission reductions to workplace safety – that can benefit enterprises. One example is the use of cobots, also known as collaborative robots, in the workplace for more hazardous tasks, resulting in a healthier and safer workspace for employees.

The greatest barrier, however, remains the perception of ESG tracking being a laborious and tedious process. According to the Harvard Business School, many ESG measures can already capture inputs effectively, but these measures unfairly presume causality in outcomes. Underlying processes were often missed and don't provide the necessary insights into those outcomes. The same report also highlights how the ESG agenda can be led astray by ill-designed measurements, burdening the business and producing lower-than-expected emissions reductions that are not commensurate with the effort and investment.

As such, having the ability to competently track ESG with the right KPIs will result in ideal outcomes - from the greening of supply chains, logistics, transportation, inventory, packaging and even material use through recycling. ESG is more than just CSR. It's about active interventions and continuous outreach; a feat that not every business is ready to switch to at a moment's notice.

The Helpful Trio - ESG, Artificial Intelligence and Dynamic Optimisation

Efficient ESG tracking begins with an approach using advanced analytics to monitor, create, store and archive critical ESG metrics with the proper measurements. Data analytics provides sufficient visibility across the organisation and enables the business to track and analyse the status quo. This helps businesses assess the current impact and quickly address low-hanging fruits in their operations and organisation. And because different organisations have different data and architecture, no single ESG execution can be the one size that fits all.

Through data analytics, businesses can utilise artificial intelligence to develop a roadmap to hit projected ESG targets in the short and long term. Next, by using analytics, artificial intelligence and machine learning, businesses can address gaps quickly and dynamically through operations optimisation. For example, businesses utilising huge amounts of electricity such as furnaces and material mixing can use this trio of technology to optimise energy use or identify potential energy leaks in their operations in near real-time, leading to additional savings for the enterprise.

Data analytics also enables inventory forecasting and supply chain management, helping businesses reduce manufacturing waste and prevent inventories from idling in the warehouse. Artificial intelligence and machine learning also bring value to the table by aiding automation and discovering crucial areas for further optimisation and improvement. With tracking and reporting automated, businesses can also provide transparency for stakeholders and regulatory compliance.

With inflation and supply chain disruptions becoming the norm, the manufacturing sector needs a sense of urgency, and invest in ESG, risk assessment and process transformation. By leveraging advanced and AI capabilities in ESG management, businesses will bring greater transparency and accountability to the marketplace, and turn over a (greener) new leaf one action at a time.