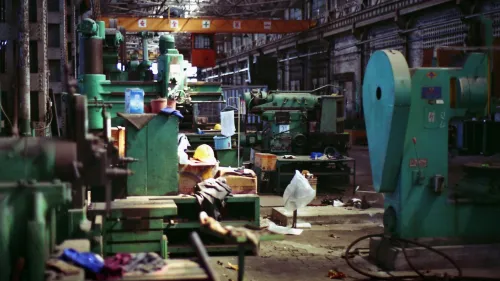

Asian suppliers still recording excess capacity for three straight months

Idle factories may drive prices down next year.

Asia’s supply chains continued to record spare capacity for the third month running in November in a latest sign of a prolonged manufacturing slump could extend through next year, according to the latest industry tracker by GEP and S&P Global.

The GEP Supply Chain Volatility Index for Asia improved to -0.24 from last month’s -0.38 reading, signalling marginal improvement across the region’s supply chains. Despite the uptick, the index remained in the negative territory and is one of the highest supplier spare capacity since the height of the pandemic in 2020.

Asian suppliers have been reporting idle capacity since the index dipped to -0.20 in September from 0.06 in August.

“Capacity at Asia’s suppliers went underutilized to one of the greatest degrees in the post-pandemic era, boding ill for the near-term outlook of global manufacturing,” the report said.

Todd Bremer, vice president for consulting at GEP said manufacturers will have greater room to cut their prices next year as factories continue to struggle with excess capacity.

READ MORE: Asia’s supply chains underutilisation hits 2020 low

The index tracks demand conditions, shortages, transportation costs, inventories and backlogs of factories worldwide on a monthly basis.

A value above 0 indicates higher utilisation and volatility in the supply chains, while a reading in the negative territory signals underutilisation of production capacity and lower volatility.

On a broader look, the GEP Global Supply Chain Volatility Index has eased to -0.34 in November from -0.41 in October, marking the eight consecutive month of excess capacity seen in factories around the world.

“This persistent, month-after-month, excess vendor capacity means that the end to the global manufacturing recession is still some way off,” said Bremer.