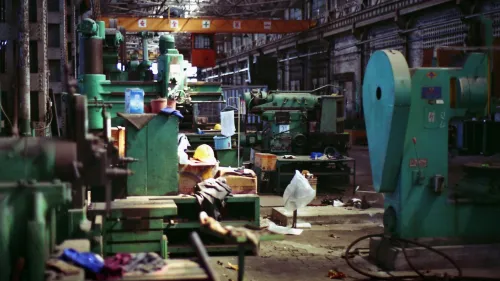

Vietnam's manufacturing sector returns to growth after four-month decline

Output expansion quickens as new orders rise for the first time since March

Vietnam's manufacturing sector staged a comeback in July, returning to growth for the first time in four months as renewed demand supported faster production increases, according to the latest S&P Global Purchasing Managers' Index (PMI).

The headline PMI reading rose to 52.4 in July, up sharply from 48.9 in June and back above the crucial 50.0 threshold that separates growth from contraction. The improvement marked the strongest upturn in business conditions for almost a year.

The recovery was driven by a return to growth in new orders, which expanded for the first time since March at the fastest pace since November last year. Companies reported strengthening customer demand, though this was partially offset by continued weakness in export markets.

US tariffs continued to weigh on foreign sales, with new export business falling for the ninth consecutive month. Several manufacturers cited the negative impact of American trade barriers on their overseas order books.

"July PMI data suggested that the Vietnamese manufacturing sector is getting back on its feet following the disruption caused to operations by the US tariff announcements in recent months," said Andrew Harker, Economics Director at S&P Global Market Intelligence.

"Although tariffs continued to cause reductions in new export orders, firms were able to secure enough business elsewhere that total new orders returned to growth."

The upturn in new business supported a marked acceleration in production growth. Output rose for the third month running, with the pace of expansion reaching an 11-month high.

Higher production requirements led manufacturers to increase their purchasing activity for the first time since last August. However, companies faced significant challenges in sourcing raw materials, resulting in supply chain disruptions.

Supplier delivery times lengthened further, with firms reporting widespread difficulties obtaining materials, particularly from overseas suppliers. These shortages contributed to declining stocks of both purchased goods and finished products.

Material shortages drove input costs higher for the second consecutive month, with the rate of price inflation reaching a seven-month peak and the fastest pace recorded so far this year.

Manufacturers passed some of these increased costs onto customers, with output prices rising at the sharpest rate in seven months, though the overall increase remained modest.

Employment Stabilises

Staffing levels showed signs of stabilisation, with the rate of job losses slowing to the smallest decline in nine months. Companies continued to reduce headcount due to spare capacity following the recent period of falling orders, but the pace of cuts moderated as output requirements increased.

Backlogs of work continued to shrink, though at the slowest rate in the current seven-month period of decline.

Whilst manufacturers remained positive about future output growth over the coming year, confidence dipped to a three-month low in July and remained well below the historical average.

Companies linked their optimism to hopes for more stable economic conditions, new product launches and increased orders. However, concerns about the ongoing impact of US tariffs continued to dampen the outlook.

"A key feature of the latest survey was the impact of difficulties sourcing raw materials," Harker noted. "If material supplies continue to cause issues in the months ahead then we may see limits to the growth rates that can be achieved by the sector."