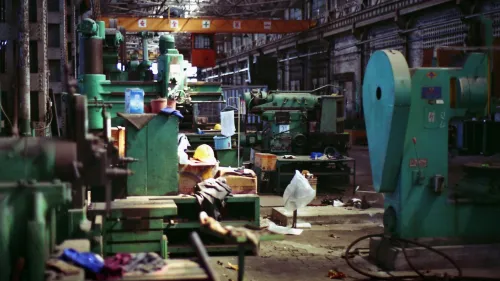

Myanmar manufacturing sector struggles as earthquake aftermath weighs on recovery

PMI shows modest recovery from April.

Myanmar's manufacturing sector remained mired in contraction in May, as producers continued to grapple with the lingering effects of the devastating earthquake that struck the country in late March.

Whilst conditions showed marginal improvement from April's severe disruption, the sector recorded its fifth consecutive month of deteriorating operating conditions.

The S&P Global Myanmar Manufacturing Purchasing Managers' Index (PMI) rose to 47.6 in May, up from April's 45.4 reading.

Whilst this represents an improvement from the previous month's earthquake-related nadir, any reading below 50 indicates ongoing contraction in manufacturing activity. The latest figures underscore the persistent challenges facing Myanmar's industrial sector as it attempts to recover from both seismic disruption and broader economic headwinds.

Demand weakness drives output decline

Manufacturing output continued to decline in May, albeit at a softer pace than the sharp contraction observed in April. The reduction in production levels reflected the ongoing weakness in demand conditions, with new orders falling for the fifth consecutive month since the beginning of 2025.

Several survey respondents attributed the decline in new business to reduced customer spending power following the earthquake, which has dampened domestic demand across the economy. The disaster's impact on infrastructure and supply chains has created a ripple effect throughout the manufacturing sector, constraining both production capacity and market access.

Employment pressures mount

The challenging operating environment has taken a toll on employment within Myanmar's manufacturing sector. Companies reduced their workforce numbers at the fastest pace in three months during May, as firms sought to align labour costs with diminished production requirements.

Survey participants reported that many workers have left the sector in search of better-paying opportunities elsewhere, with some pursuing employment abroad or returning to their home towns. This labour market fluidity has added another layer of complexity for manufacturers attempting to maintain operations during an already difficult period.

Cost pressures ease despite supply challenges

In a rare positive development, inflationary pressures moderated significantly in May. Input costs rose at the slowest rate in nearly two and a half years, despite some firms reporting higher expenses related to material shortages and increased transportation costs.

The easing of cost pressures was primarily attributed to weak demand conditions, which reduced competitive pressure on suppliers and allowed manufacturers to negotiate more favourable terms. This softer inflation environment enabled companies to raise their output prices at the most modest pace in 18 months.

Inventory management reflects cautious approach

Manufacturing firms continued to operate in retrenchment mode, reducing both purchasing activity and inventory levels. Companies curtailed their stocks of both raw materials and finished goods, citing weak production requirements and ongoing material shortages as key factors driving these decisions.

The reduction in inventory levels, whilst representing a rational response to current market conditions, may limit manufacturers' ability to respond quickly to any upturn in demand once market conditions begin to improve.

Cautious optimism for future outlook

Despite the challenging current environment, Myanmar's manufacturers maintained a positive outlook for production over the coming year. Confidence levels strengthened slightly compared to the previous month, suggesting that firms believe the current difficulties are temporary rather than structural.

However, the degree of optimism remained below the survey's long-run average, indicating that whilst manufacturers expect eventual recovery, they remain cautious about the pace and timing of any improvement in operating conditions.

Economic implications

The continued contraction in Myanmar's manufacturing sector highlights the broader economic challenges facing the country as it attempts to recover from natural disaster whilst navigating an uncertain global economic environment.

The manufacturing PMI serves as a key barometer of economic health, and the sustained weakness suggests that Myanmar's economic recovery may be more protracted than initially anticipated.

The moderation in cost pressures provides some relief for manufacturers, but the ongoing weakness in demand and employment trends suggest that the sector faces a challenging path back to growth.

Policymakers will be closely monitoring these indicators as they consider measures to support economic recovery and rebuild confidence in Myanmar's industrial sector.

The data, collected between 12-21 May 2025, provides the most recent snapshot of conditions within Myanmar's manufacturing sector and will be crucial for understanding the trajectory of the country's broader economic recovery efforts.