Finance teams move to real-time planning in manufacturing

Leading manufacturers use an advanced planning platform.

Manufacturers must optimise financial planning as it can improve standard cost accuracy by 1% to 5%, cut budgeting cycle time by 30% to 50%, and save up to 5,000 hours of planning effort per year, according to a Kearney report.

To achieve these benefits, leading manufacturers use an advanced planning platform for manufacturing finance planning for standardisation and automation.

According to Kearney, manufacturing finance does not have to begin planning six months before budgets are due, when estimates may not properly reflect the future.

Instead, the function can delay efforts until teams have submitted preliminary sales volume projections, allowing finance and operations to continuously update their assumptions and inputs.

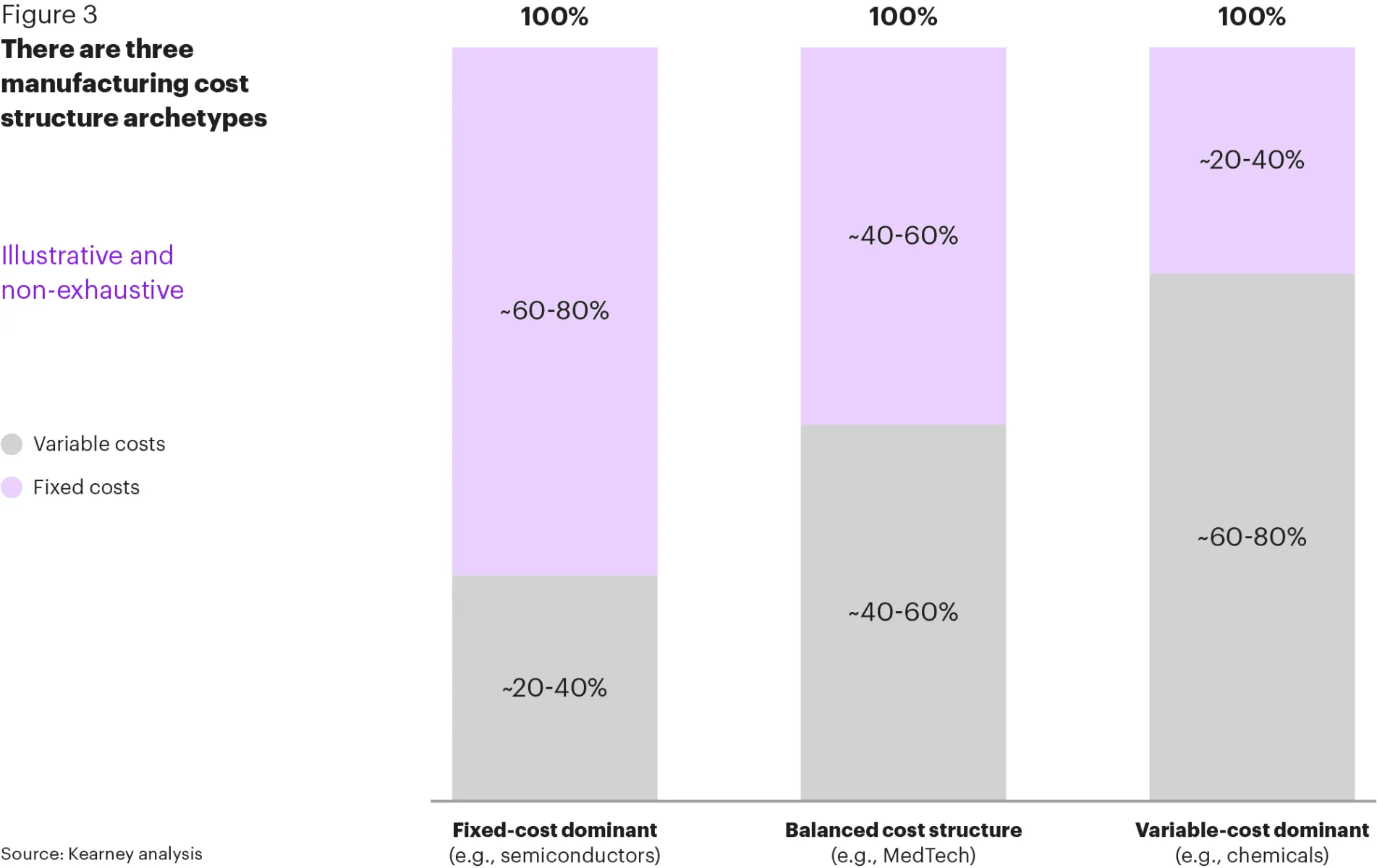

Companies with high material costs and slim margins, like chemical producers, need to update costs often. If an ingredient price spikes, a product might become unprofitable. Without rapid cost checks, the company would only realise losing money after it is too late.

Conversely, companies like semiconductor manufacturers have very high fixed costs. Allocating these large fixed costs to each product is complex but crucial. Planning tools help them quickly and accurately assign a portion of the plant's cost to each chip.