PT Cemindo Gemilang eyes cement plant upgrades

Its carbon injection technology strengthens concrete whilst cutting carbon emissions.

PT Cemindo Gemilang Tbk is expanding its cement facilities in Indonesia after launching its carbon injection technology from its Canadian partner, as it seeks to boost growth amidst the nation’s resurgent cement and building industry.

“In Jakarta, this technology helps curb pollution by absorbing CO2 directly into the concrete,” Akhmad Syamsuddin, operational director at PT Motive Mulia, a unit of PT Cemindo Gemilang, told Manufacturing Asia.

The company’s carbon injection technology is provided by CarbonCure Technologies, a Canadian green technology company.

The process, in which captured CO2 is injected into fresh concrete, where it mineralizes and becomes permanently embedded, not only reduces carbon emissions but also strengthens concrete structure, Syamsuddin said in an emailed reply to questions.

“The chemical reaction during this process increases concrete density, making it stronger and more durable,” he pointed out.

There has been resurgent activity in Indonesia’s cement sector after the COVID-19 pandemic reduced demand, according to Asian Insiders. The Southeast Asian nation’s cement industry contributes about 5% to economic output and employs as many as a million people, it said.

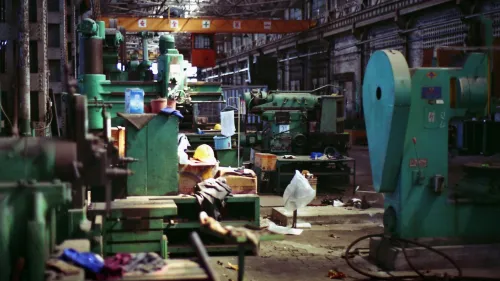

PT Cemindo Gemilang, which makes the Semen Merah Putih cement brand in Indonesia, also operates in Vietnam through unit Chinfon Cement Corp. In Indonesia, it has an integrated cement plant supported by a deep sea port facility in Bayah, Banten.

It has high-end grinding plants in Java, Sumatra, and Kalimantan, where the company operates a fully equipped cement terminal that can reach all markets.

PT Cemindo Gemilang’s carbon injection technology, which cuts cement usage by as much as 4%, has been used in several projects, including the construction of Sinar Mitbana Mas’s Club House at Hiera township development in BSD City in Jakarta.

The project shows how low-carbon concrete innovation can be integrated in green development.

“Hiera township development is built on sustainability principles, including the adoption of environmentally friendly construction technology,” Ferianda, Technical Planning Department head at Sinar Mitbana Mas, told reporters in Jakarta last month.

At the same event, Surindro Kalbu Adi, director of Commercial and Logistics at Semen Merah Putih, said sustainability is a core business principle integrated into all their units — upstream for Semen Merah Putih, and downstream for concrete brand Beton Merah Putih.

In the upstream business, Semen Merah Putih uses sustainable practices such as waste heat recovery units and environment-friendly fuels. “The implementation of carbon injection technology for Beton Merah Putih is an innovation to meet market demands, " he added.

Syamsuddin said the biggest challenge is the cost of equipment and CO2 distribution at each plant. To address this, Beton Merah Putih plans to install carbon injection systems across all its plants to reduce costs.

“We are seeing a positive trend where more construction partners are transitioning to green concrete,” he said. “We hope the positive impact of this technology continues to expand across various strategic projects.”