Circular business models: Unlocking the next phase of growth in Asia’s manufacturing sector

By Frédéric GodemelTo achieve real, lasting sustainability, organisations must move beyond carbon targets.

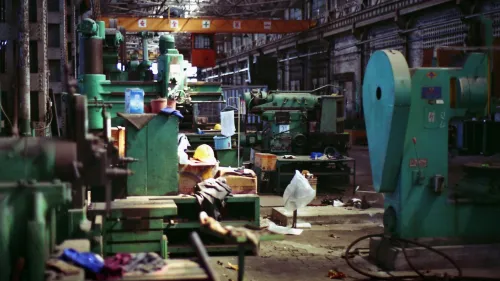

As cost pressures rise and supply chains remain unpredictable, more manufacturers in Asia are adopting circular business models.

By designing products for reuse, extending asset lifecycles, and optimising material flows, circularity is helping businesses build resilience while cutting waste and emissions. The result? Lower costs, stronger supply chains, and a differentiated position in a sustainability-conscious market.

The shift from a linear “take-make-waste” model to a circular one isn’t just good for the planet – it’s increasingly vital for competitiveness. Circular approaches unlock operational efficiency, open new revenue streams such as repair or refurbishment, and help meet tightening environmental regulations across key markets like the European Union, Japan, and South Korea.

Leading firms are already moving. Woolworths is decarbonising logistics in Australia. Tata Power is embedding circularity in India’s energy ecosystem. Japanese and South Korean manufacturers are redesigning operations around durability and reuse.

Their actions reflect a broader industry shift: according to Gartner, nearly 70% of CEOs now view sustainability as a driver of growth. Already, two-thirds of Fortune Global 500 companies have made substantial commitments to addressing climate impacts across their total value chains.

But ambition alone won’t deliver results. To achieve real, lasting sustainability, organisations must move beyond carbon targets and address the full material footprint of their operations.

That means embedding circularity – not just reducing emissions, but rethinking how materials are sourced, used, and recirculated. Yet, global progress is heading in the wrong direction: global circularity has declined from 9.1% in 2018 to 7.2% in 2023, even as consumption soars.

In the past five years alone, humanity used over 500 gigatonnes of materials – more than a quarter (28%) of everything consumed since 1900. For manufacturers, this signals both a risk and an opportunity: reimagining value chains through circularity is no longer optional – it’s a strategic imperative.

If circularity is the true test of sustainable progress, it’s time for bold action. Every business has a crucial role to play.

Challenging the status quo of consumption and waste

Circularity is an economic model that aims to eliminate waste, preserve resources, and reuse materials. A stark contrast to the linear ‘take-make-waste’ model that most current economies are built upon.

Take the life of a bottle of water for example: oil is drilled from the earth and refined into polyethylene terephthalate – take. Then this is moulded into bottles that are filled with water – make.

Finally, they are consumed once and then discarded – waste. Just 12% of the world’s plastic bottles are recycled, and meanwhile, the 88% of remaining bottles are tossed into landfill, where they can take up to 450 years to decompose.

This unsustainable pattern of consumption significantly contributes to greenhouse gas emissions and biodiversity loss. Transitioning to a circular economy could drastically reduce the materials we use by 70%, creating better resource utilisation. So, how exactly can a business become more circular?

Here are three practical strategies companies can adopt to turn circularity into a source of value, resilience, and leadership.

Designing with purpose – for longevity and performance

At the heart of any successful circularity model is eco-design – ensuring that products are developed for durability, reuse, and minimal waste.

Building on this foundation, businesses must evolve from a traditional and transactional sales approach to an ‘as-a-service’ model. To support this shift, companies should consider supplementing sales with rental, repair, and support services.

This simultaneously extends product lifecycles, reduces waste, and creates new growth opportunities. By offering second-hand tech and trade-in programmes, companies can meet the demand for affordable, eco-friendly options. This model reduces waste, boosts customer loyalty, and drives long-term profits.

Responsible sourcing and smart operations

The first principle organisations should consider when building their circularity framework is use better. This calls for the responsible sourcing of materials to optimise manufacturing and minimise waste. For instance, sourcing best-in-class materials ensures reduced environmental and social impact throughout the supply chain.

Smart manufacturing is also key. Facilities that incorporate machine learning-enabled prototyping, smart planning, and generative AI-enhanced maintenance can significantly boost productivity while reducing resource consumption.

Beyond manufacturing, circularity demands companies to address sustainability across their entire value chains. Sustainable supply chain programmes have already been launched in various sectors, such as global healthcare, the semiconductor industry, as well as mining, materials, and minerals. These programmes help companies responsibly source materials, reduce emissions, and eliminate waste at every link.

Maximising product lifespans – use longer, use again

The second principle is to extend the lifespan of products and use longer. Businesses must anticipate the need for equipment by opting for condition-based repair, digitally enabled maintenance, and equipment modernisation. Reparability and circularity services are pivotal in extending asset lifespans.

Finally, the third principle is to use again. Remanufacturing and reselling equipment and assets that have reached the end of their initial use – instead of discarding them – reduces waste and emissions while conserving resources. This concept encourages businesses to recirculate products, parts, and materials within the economy.

Circularity: A strategic lever for Asia Pacific

In an era of shifting regulations, resource constraints, and rising consumer expectations, circularity isn’t just the right thing to do – it’s a strategic imperative.

For businesses in Asia’s fast-growing markets, circularity offers a path to operational efficiency, cost-savings, and long-term resilience. It strengthens supply chains, boosts innovation, and positions companies to lead in the next phase of sustainable growth.

Circularity is no longer optional. It’s a competitive advantage for those ready to rethink, redesign, and regenerate for a better tomorrow – in Asia Pacific and beyond.